RAW MATERIAL PROCESSING

We use fiber laser cutting centers and automatic bending machines for the precision and quality of the raw material used to build the fans.

ASSEMBLY

Fans are assembled with the utmost attention to detail, using templates and equipment specifically designed to meet accurate dimensional tolerances both in terms of the structure and building the impellers.

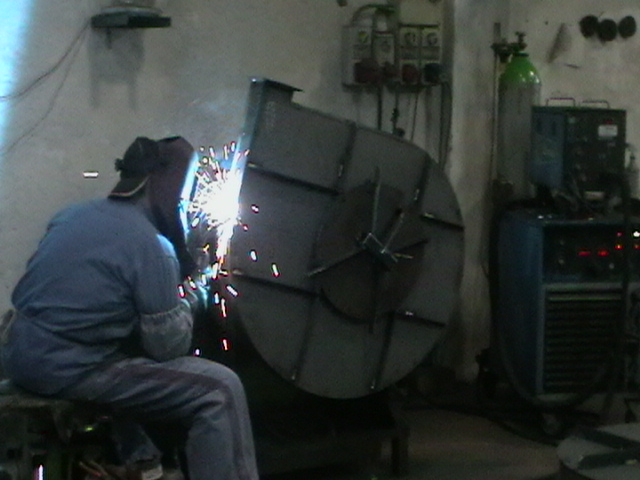

WELDING

Specialized operators manually weld the structure while our impellers are welded in an automated robotic welding system.

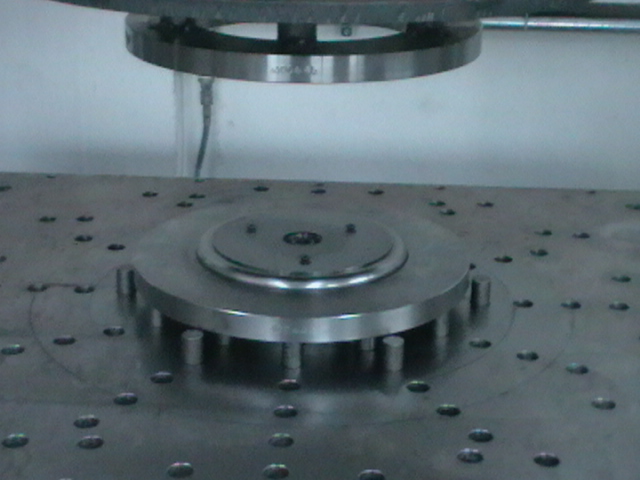

ASSEMBLY AND QUALITY CONTROL

All our products are subject to visual and dimensional inspections. Final assembly and testing are performed in-house by specialized personnel.

SERVICES

Our highly flexible technical department is available to analyze, design, and develop customized special fans on request.

Services

Processing